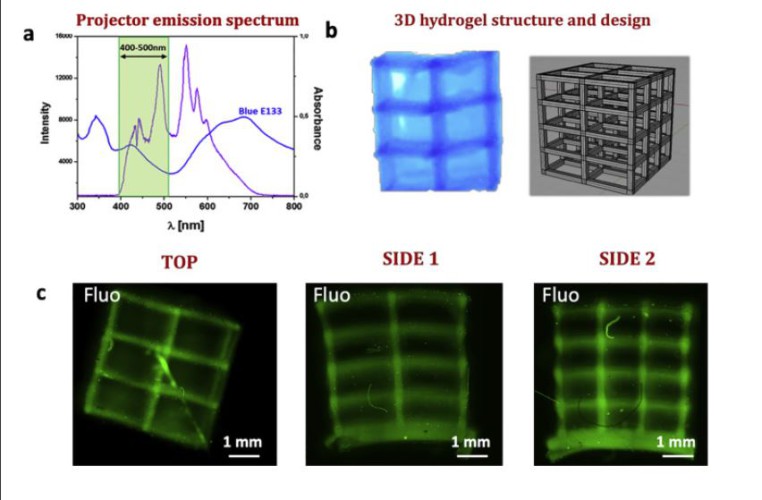

Biomimetic hydrogels offer several opportunities in medical applications, according to a group of researchers in a paper entitlted “Polysaccharide hydrogels for multiscale 3D printing of pullulal scaffolds.” But the generation of synthetic microenvironments that simulate the effects of natural tissue niches on cell growth and differentiation requires new methods to control hydrogel feature resolution, biofunctionalization and mechanical properties. In the paper, the researchers show how this can be achieved by using a 3D printable pullulan-based hydrogel with tunable mechanical properties.

Pullulan is a non-ionic linear polysaccharide that is naturally produced from starch. It has many advantages: it is biodegradable, edible, bio- and blood-compatible, non-toxic, non-immunogenic, non-mutagenic and non-carcinogenic, as well as being easily soluble in water, which allows a clear and viscous hydrogel to be prepared. It has been proposed as an anti-adhesive barrier layer for the prevention of postoperative problems, and is widely used in cosmetics. It has anti-free-radical properties and has been used in nanofibers or coatings for food preservation, as well as in applications in tissue engineering and regenerative medicine.

GBA Group is a leading group of laboratories with a solid reputation backed by over…

Now, INTECH CO. developed stripping tape to collect Dead skin cell. - Basic Skin Research…

K-Beauty's Global Takeover: A Success Story The Korean beauty industry has achieved an unprecedented milestone:…